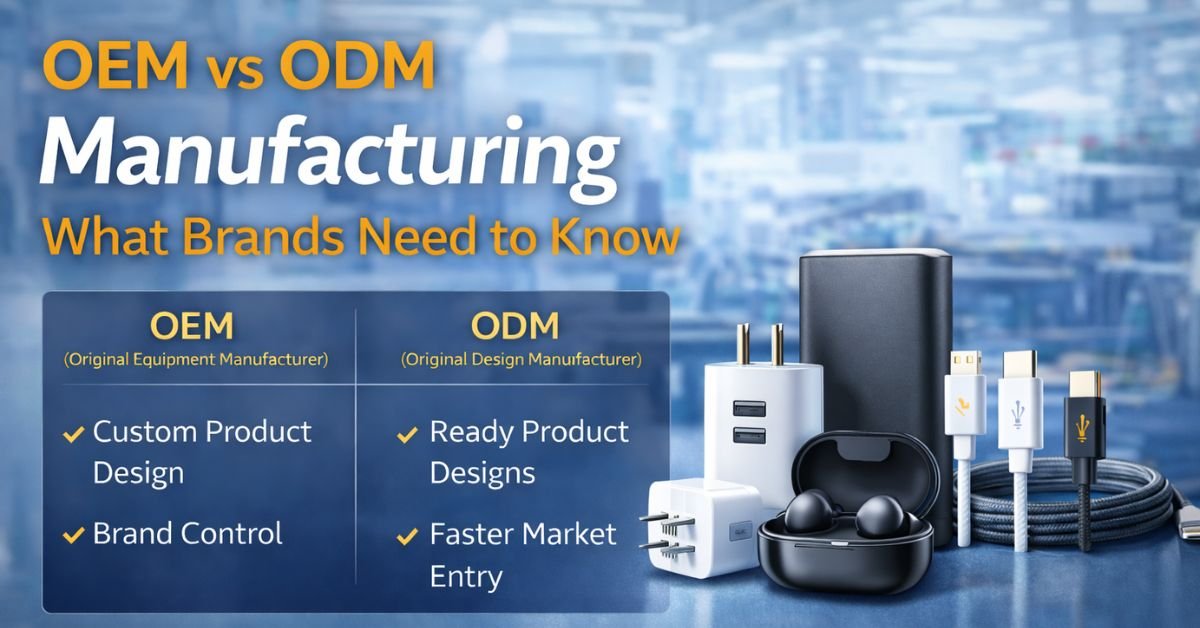

As brands grow in the electronics and mobile accessories market, one of the most critical decisions they face is how to scale manufacturing efficiently. At this stage, terms like OEM and ODM manufacturing become central to business strategy.

Many growing brands hear these terms but do not fully understand the difference – or more importantly, which model suits their growth goals. Choosing the wrong manufacturing approach can lead to higher costs, slower launches, and operational complexity.

This guide explains OEM vs ODM manufacturing, how each model works, their advantages and limitations, and what brands should consider before scaling production.

Also Read: Emerging Trends in Electronics Manufacturing -2026

Understanding OEM Manufacturing

OEM stands for Original Equipment Manufacturer. In this model, a manufacturer produces products based on the brand’s specifications, designs, or requirements, which are then sold under the brand’s own name.

How OEM Manufacturing Works

- The brand defines product specifications

- The manufacturer handles production

- Products are branded and packaged for the client

- The brand controls positioning and marketing

OEM manufacturing is widely used by brands that want customization and control without building factories.

Understanding ODM Manufacturing

ODM stands for Original Design Manufacturer. In this model, the manufacturer already has pre-designed products, which brands can select, customize slightly, and sell under their own label.

How ODM Manufacturing Works

- Manufacturer develops product designs

- Brand selects from existing models

- Minor customization (logo, packaging, specs)

- Faster launch compared to OEM

ODM is often preferred by brands that want quick market entry with lower development effort.

Key Differences Between OEM and ODM Manufacturing

| Aspect | OEM Manufacturing | ODM Manufacturing |

| Product Design | Brand-driven | Manufacturer-driven |

| Customization | High | Limited |

| Time to Market | Moderate | Faster |

| R&D Involvement | Brand + Manufacturer | Mostly Manufacturer |

| Cost Structure | Higher flexibility | Lower initial cost |

| Brand Differentiation | Strong | Moderate |

Understanding these differences helps brands align manufacturing with business goals.

Also Read: OEM Mobile Accessories Manufacturer: What to Expect from a Trusted Partner

Which Manufacturing Model Is Better for Scaling?

There is no universal answer. The right choice depends on where the brand is in its growth journey.

OEM Is Ideal When:

- Brand wants unique product specifications

- Differentiation is important

- Long-term brand identity matters

- The brand has clarity on product roadmap

ODM Is Ideal When:

- Speed to market is critical

- The brand is testing new categories

- Budget and risk need to be controlled

- Customization needs are minimal

Many successful brands start with ODM and gradually move to OEM as they scale.

Cost Considerations Before Scaling

Manufacturing decisions directly impact margins.

OEM Cost Factors:

- Product development effort

- Tooling and testing

- Custom components

- Lower flexibility for very small quantities

ODM Cost Factors:

- Lower development costs

- Standardized components

- Faster ROI

- Slightly limited uniqueness

Brands planning to scale should evaluate long-term profitability, not just initial cost.

The Importance of Manufacturing Partners

Whether choosing OEM or ODM, the manufacturing partner plays a critical role in success. A reliable partner ensures:

- Consistent quality

- On-time production

- Transparent processes

- Scalable capacity

This is why many brands prefer working with manufacturers that support both OEM and ODM models, allowing flexibility as the brand grows.

SigmaVizin Electronics: Supporting OEM & ODM Growth

SigmaVizin Electronics operates as a B2B-focused mobile accessories manufacturer, supporting brands across both OEM and ODM manufacturing models.

Rather than offering a one-size-fits-all approach, SigmaVizin works closely with brands to understand:

- Growth stage

- Market positioning

- Customization needs

- Volume planning

This flexible approach allows brands to start lean and scale strategically, without changing manufacturing partners frequently.

Why Hybrid Models Are Gaining Popularity

Many brands today adopt a hybrid approach:

- ODM for faster launches in some categories

- OEM for flagship or high-volume products

Manufacturers like SigmaVizin Electronics make this transition smoother by offering:

- Customization support

- Structured production planning

- Quality-focused processes

This helps brands evolve without operational disruption.

Quality Control: Critical in Both OEM & ODM

Regardless of the model chosen, quality control remains non-negotiable.

Reliable manufacturers ensure:

- Component-level testing

- Performance consistency

- Safety compliance

- Batch-level quality checks

For brands scaling operations, consistent quality builds trust with distributors, retailers, and end users.

Regulatory & Compliance Considerations

As brands scale, they often expand into new regions or retail channels. This requires:

- Compliance-ready products

- Proper documentation

- Standardized manufacturing practices

Working with experienced manufacturers simplifies compliance management and reduces market-entry risks.

OEM vs ODM: Strategic Decision, Not Just Operational

Choosing between OEM and ODM manufacturing is not just a production decision — it is a brand strategy decision.

OEM supports:

- Brand uniqueness

- Long-term differentiation

ODM supports:

- Speed

- Efficiency

- Market testing

Brands that evaluate these models carefully are better positioned to scale sustainably.

Also Read: Best OEM Mobile Accessories Manufacturer in India

Final Thoughts

OEM and ODM manufacturing both play important roles in the growth of electronics and mobile accessories brands. The key lies in choosing the right model at the right stage and working with a manufacturing partner that understands scaling challenges.

Manufacturers like SigmaVizin help brands navigate this decision by offering flexible OEM and ODM solutions, quality-driven production, and long-term partnership support.

For brands planning to scale, understanding OEM vs ODM is not optional — it is essential.

FAQ

❓ What is the main difference between OEM and ODM manufacturing?

OEM focuses on brand-defined product specifications, while ODM involves manufacturer-designed products that brands can rebrand and customize slightly.

❓ Is OEM or ODM better for new brands?

ODM is often better for new brands due to faster launch and lower development effort, while OEM suits brands aiming for differentiation.

❓ Can a brand use both OEM and ODM manufacturing?

Yes, many brands use a hybrid approach — ODM for quick launches and OEM for core or high-volume products.

❓ How does OEM manufacturing help in brand building?

OEM allows brands to control product design, features, and positioning, helping create stronger brand identity.

❓ What should brands check before choosing a manufacturer?

Brands should evaluate quality control, scalability, communication transparency, and experience in OEM/ODM manufacturing.

❓ How does SigmaVizin Electronics support scaling brands?

SigmaVizin Electronics supports brands with flexible OEM and ODM manufacturing, quality-focused processes, and scalable production planning.