Introduction: Why OEM vs. ODM Matters for Your Business

In today’s highly competitive electronics industry, companies are under constant pressure to innovate, reduce costs, and deliver products that stand out in the market. Whether you’re a startup launching a new gadget or an established brand expanding your product portfolio, choosing the right manufacturing model is crucial.

Two of the most widely adopted approaches are OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing). While both involve working with a leading electronics manufacturer, the differences between OEM and ODM can determine your product’s success, cost structure, and speed-to-market.

This blog will help you understand OEM vs. ODM, their advantages and challenges, and guide you in choosing the right path for your business. We’ll also highlight how electronics manufacturers in India, like SigmaVizin Electronics, are bridging the gap for global B2B clients through flexible OEM & ODM solutions.

What is OEM (Original Equipment Manufacturing)?

OEM stands for Original Equipment Manufacturing, where a company provides the design, intellectual property (IP), and specifications of a product, and the electronics manufacturer handles the production.

In simpler terms:

- You design it.

- Your manufacturing partner builds it.

Key Features of OEM

- Product concept and design come from the client.

- The electronics manufacturer for OEM focuses mainly on assembly, component sourcing, and quality control.

- Final product carries the client’s brand name.

Example in Electronics

Imagine a startup in India designing a smart IoT-enabled power bank. They create the blueprint, design files, and required specifications. A leading electronics manufacturer in India then produces the power bank exactly as per those designs, ensuring high-volume production and quality compliance.

What is ODM (Original Design Manufacturing)?

ODM stands for Original Design Manufacturing, where the electronics manufacturer not only produces but also designs and develops the product. The client can then rebrand and sell it under their name.

In simpler terms:

- Your manufacturing partner designs it.

- You market it under your brand.

Key Features of ODM

- Product concepts, R&D, and prototypes come from the manufacturer.

- Businesses can customize certain features like color, branding, or packaging (white-label solutions).

- Quicker and often more cost-effective compared to OEM.

Example in Electronics

Consider a brand that wants to launch Bluetooth TWS earbuds but does not have in-house design capabilities. A B2B electronics supplier offering ODM services provides a ready-made design. The brand customizes the logo, packaging, and minor features, and brings the product to market in weeks instead of months.

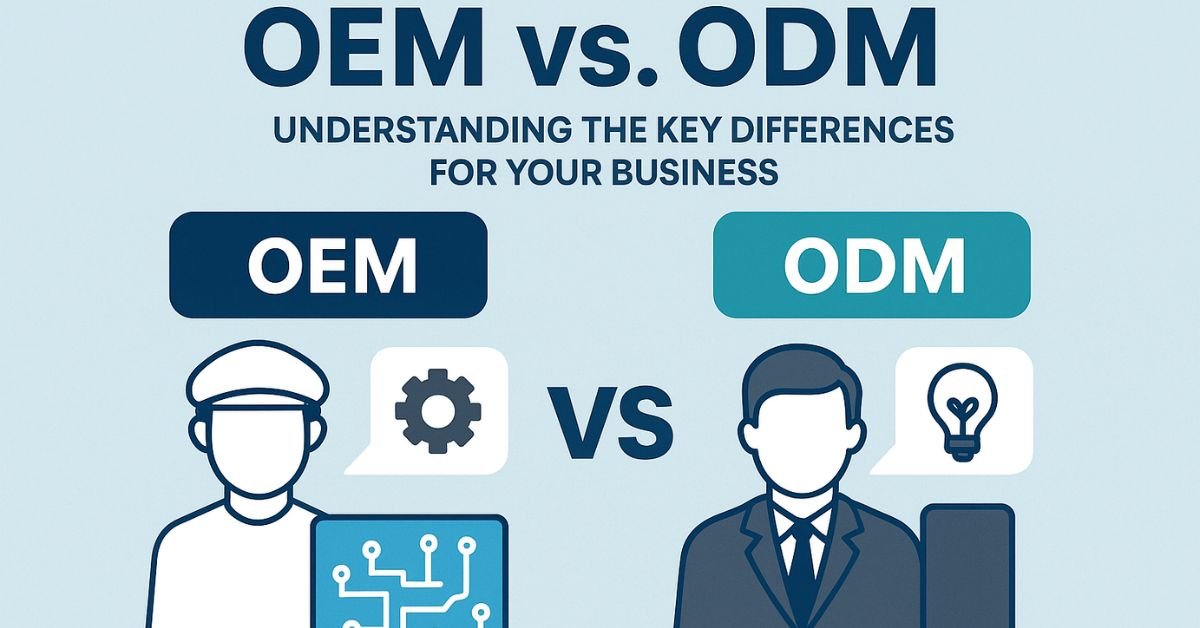

OEM vs. ODM: Comparative Analysis

Choosing between OEM and ODM depends on multiple factors, including your company’s resources, expertise, and long-term strategy. Let’s break it down:

1. Design & Intellectual Property

- OEM: Client owns the design and IP. Full control but requires significant R&D investment.

- ODM: Manufacturer owns the design. Faster market entry but less differentiation.

2. Time-to-Market

- OEM: Longer timelines due to design, prototyping, and testing.

- ODM: Faster launch since the design is already developed.

3. Cost Implications

- OEM: Higher upfront costs (R&D, prototyping, testing). Lower per-unit cost at scale.

- ODM: Lower upfront investment. May pay a premium per unit for flexibility.

4. Customization Options

- OEM: Full customization – from circuit boards to casing design.

- ODM: Limited customization – mostly branding, color, and packaging.

5. Best Suited For

- OEM: Established companies with R&D budgets and long-term product strategies.

- ODM: Startups, SMEs, or businesses testing new markets with limited resources.

Advantages & Challenges

Advantages of OEM

- Complete ownership of product design and IP.

- Strong brand identity and differentiation.

- Ability to scale production with a trusted OEM & ODM electronics manufacturer.

Challenges of OEM

- High initial costs for design and development.

- Longer lead times before market launch.

- Requires strong technical expertise and market insights.

Advantages of ODM

- Faster time-to-market with pre-developed designs.

- Lower upfront investment – ideal for startups.

- Access to manufacturer’s R&D expertise and proven product lines.

Challenges of ODM

- Limited customization options.

- Product design may not be unique (other brands may use similar designs).

- Dependency on the manufacturer’s innovation pipeline.

Also Read: SigmaVizin—Your Trusted Partner for OEM & ODM Electronics Manufacturing

How Electronics Manufacturers in India Support OEM & ODM Needs

India has rapidly emerged as a global hub for electronics design services, contract manufacturing, and white-label solutions. With government initiatives like “Make in India” and rising demand for localized production, businesses worldwide are turning to electronics manufacturers in India for both OEM and ODM support.

For example, SigmaVizin Electronics Pvt. Ltd., a trusted OEM & ODM electronics manufacturer, offers:

- End-to-end manufacturing services for power banks, chargers, data cables, TWS earbuds, and more.

- Flexible OEM partnerships where brands retain full control over product design.

- Ready-to-market ODM solutions with customizable branding for quicker launches.

- Strong supply chain, quality testing, and B2B-focused production capabilities.

By partnering with such manufacturers, businesses can balance innovation, cost-efficiency, and speed-to-market.

Practical Tips for Choosing Between OEM and ODM

If you’re a business owner wondering whether to go for OEM or ODM, consider these factors:

- Assess Your Resources

- If you have strong R&D and design teams → OEM is ideal.

- If you’re short on technical expertise or budget → ODM is practical.

- Define Your Business Goals

- Long-term brand building with unique IP → Choose OEM.

- Quick entry into competitive markets → Choose ODM.

- Consider Market Dynamics

- For fast-moving electronics like earphones or chargers → ODM provides agility.

- For niche products requiring differentiation → OEM offers greater control.

- Evaluate Your Manufacturing Partner

- Look for a leading electronics manufacturer with proven expertise in both models.

- Ensure they provide services like prototyping, product customization, and global quality compliance.

Conclusion: Making the Right Choice

The debate of OEM vs. ODM isn’t about which model is better—it’s about which model is right for your business at a particular stage.

- OEM empowers brands that want complete control, long-term product differentiation, and IP ownership.

- ODM benefits companies seeking speed, cost-efficiency, and market-ready solutions.

By partnering with a trusted electronics manufacturer for OEM & ODM, especially in India, businesses can scale efficiently and compete globally.

At SigmaVizin Electronics, we help B2B clients strike the perfect balance between customization, innovation, and speed. Whether you need a manufacturing partner for OEM designs or white-label ODM solutions, our expertise ensures your products are built to succeed in global markets.