Introduction

Choosing the right electronics manufacturing company can make or break your business success. From ensuring product quality to meeting timelines and managing costs, your manufacturing partner plays a pivotal role in bringing your vision to life. A poor decision could lead to costly delays, product recalls, or strained customer relationships. On the other hand, the right partner becomes an extension of your team, helping you scale efficiently and maintain a competitive edge.

In today’s fast-paced and innovation-driven market, businesses face the dual challenge of speed and quality. Whether you’re an entrepreneur developing your first product, an engineer scaling up an existing design, or a business owner seeking to diversify your portfolio, finding a reliable OEM & ODM electronics manufacturer is a critical step.

This comprehensive guide will walk you through everything you need to know to make an informed choice—from identifying your needs to evaluating a manufacturer’s capabilities. Along the way, we’ll also highlight why SigmaVizin, a leading electronics manufacturer in India, has become the trusted partner for businesses worldwide.

Understanding Your Needs First

Before approaching a manufacturer, it’s essential to define your requirements clearly. This preparation ensures you engage the right partner who aligns with your goals. Ask yourself these key questions:

Product Type & Complexity

What kind of product are you building? Is it a simple printed circuit board (PCB), a consumer gadget, or a complex IoT-enabled device? The more complex your product, the more critical it becomes to work with a manufacturer who has specialized experience.

Volume & Scalability

Are you starting with a small pilot batch, or do you anticipate scaling to large-volume production? Some manufacturers specialize in prototyping and low-volume runs, while others excel at mass production. Your chosen partner should have the flexibility to grow with your business.

Also Read: SigmaVizin—Your Trusted Partner for OEM & ODM Electronics Manufacturing

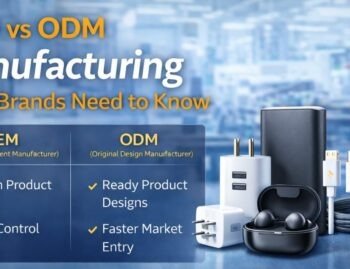

OEM vs. ODM Needs

Understanding the difference between OEM and ODM is fundamental:

- OEM (Original Equipment Manufacturing): You provide the design, and the manufacturer handles production.

- ODM (Original Design Manufacturing): You share your concept, and the manufacturer designs, develops, and manufactures the product for you.

This distinction is critical because your partner’s design and R&D capabilities will matter greatly if you need ODM services. SigmaVizin excels in both models, offering businesses the flexibility to innovate and scale.

Budget & Cost Structure

Transparent pricing is essential. Unexpected costs during production can derail your financial planning. Discuss cost breakdowns upfront—materials, tooling, labor, logistics, and after-sales services—to ensure alignment.

Timeline

Define your deadlines for prototyping, certifications, pilot production, and mass rollout. Delays can mean missed opportunities in fast-moving markets. A dependable electronics manufacturer for OEM & ODM will provide realistic timelines and stick to them.

Also Read: OEM vs. ODM: Understanding the Key Differences for Your Business

Core Criteria for Evaluating an Electronics Manufacturer

Once your needs are clear, evaluate potential partners using these core criteria.

1. Expertise and Experience

Look for a manufacturer with a proven track record in your product category. Industry experience often translates into practical problem-solving, better quality, and faster time-to-market. A diverse portfolio also signals versatility and resilience.

At SigmaVizin, for instance, we have supported projects across consumer electronics, industrial automation, and medical devices—making us a trusted B2B electronics manufacturer with cross-industry expertise.

2. Quality Control and Certifications

Quality is non-negotiable. Ensure your manufacturing partner follows strict quality management systems (QMS). Look for certifications such as:

- ISO 9001: General quality management.

- ISO 13485: Medical devices.

- RoHS compliance: Restriction of hazardous substances.

Additionally, ask about in-house testing protocols—such as functional testing, burn-in testing, and reliability checks—that safeguard your product before it reaches customers.

3. Manufacturing Capabilities and Technology

Evaluate the manufacturer’s technological infrastructure. Do they use SMT (Surface Mount Technology) lines for PCB assembly? Can they handle through-hole assembly and final box builds? Do they have automated testing systems?

Modern, well-equipped facilities reduce errors and enhance efficiency. SigmaVizin’s state-of-the-art facilities in India are built with advanced machinery, ensuring consistency, speed, and scalability.

4. Supply Chain Management

A strong supply chain is the backbone of reliable manufacturing. Assess how your partner sources electronic components, manages inventory, and mitigates risks such as global shortages. Manufacturers with established supplier networks can secure components faster and at better costs—reducing the chances of production halts.

5. R&D and Design Capabilities (Especially for ODM)

For ODM projects, design and engineering expertise are invaluable. A manufacturer who offers R&D support can help you refine your idea, prototype quickly, and optimize for mass production. This not only saves time but also ensures your product is market-ready. SigmaVizin’s in-house design team provides end-to-end support, enabling clients to transform concepts into commercial successes.

6. Communication and Customer Support

Transparent communication builds trust. A good partner will:

- Assign you a dedicated account manager.

- Provide regular progress updates.

- Be responsive to changes and concerns.

Poor communication often leads to misunderstandings, delays, or hidden costs—issues that businesses cannot afford.

7. Location Advantages

Choosing an electronics manufacturer in India offers unique benefits:

- Cost-effectiveness compared to Western markets.

- Skilled workforce with strong technical expertise.

- Faster turnaround for domestic businesses.

- Easier communication across time zones compared to East Asian regions.

Supporting local or regional manufacturing also reduces shipping costs and supply chain risks.

The SigmaVizin Advantage – Why We Are the Right Choice

Having understood the key criteria, let’s look at why SigmaVizin is the ideal partner for your business.

OEM & ODM Expertise

As a leading OEM & ODM electronics manufacturer, we empower businesses to innovate confidently. Whether you bring us a complete design or just an idea, our team can execute with precision and creativity.

State-of-the-Art Facility in India

Our advanced manufacturing units in India are equipped with modern SMT lines, automated testing setups, and assembly stations. This ensures consistent product quality while maintaining cost-efficiency—a major advantage of working with a B2B electronics manufacturer.

Comprehensive Service Offering

From concept to design, prototyping, certification support, mass production, and logistics—we provide end-to-end services under one roof. This holistic approach saves our clients both time and money.

Commitment to Quality

Quality is our cornerstone. Our adherence to global standards and rigorous testing protocols ensures that every unit leaving our facility meets client expectations.

Customer-Centric Approach

We don’t just deliver products; we build partnerships. Our dedicated support team ensures that communication is seamless and your concerns are addressed promptly.

Proven Track Record

We have successfully collaborated with clients across industries such as consumer electronics, industrial automation, wearables, and healthcare devices. These success stories demonstrate our versatility and reliability as a trusted electronics manufacturer in India.

Conclusion

Choosing the right electronics manufacturing company is not just a sourcing decision—it’s a strategic partnership that defines your product’s success. From expertise and quality to technology and communication, every factor plays a crucial role in ensuring smooth operations and long-term growth.

With proven OEM & ODM capabilities, advanced facilities, and a customer-first mindset, westands out as the partner of choice for businesses worldwide.

Don’t leave your product’s success to chance. Partner with a leading electronics manufacturer who understands your vision. Contact Us Today to discuss your next project.